A custom sofa is a piece of furniture that doesn’t yet exist, and that has to be created from start to finish. This process often starts with an idea, an inspiration or a need to be met. Here’s an example of such a process.

When we think of a bench, we often have in mind a quite simple piece of furniture with a seat and a backrest, straight and functional. It is classical, inviting and more comfortable than an unpadded chair. But here, the project was a bit more challenging. LUWISS expertise and experience helped to bring it to life.

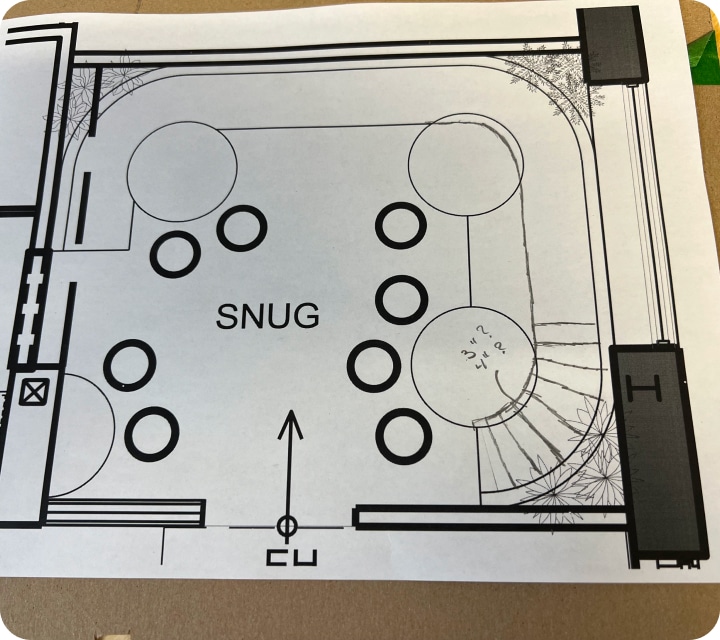

The client sent these two elements as a starting point. The request was to recreate a similar effect in a delimited resto-bar space.

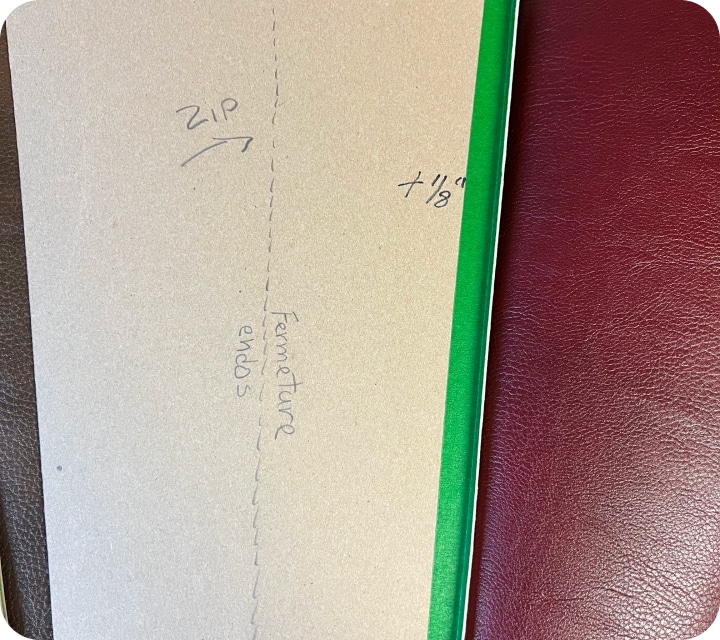

The customer was looking for a leatherette similar to the one in the photo, but in a more caramel/crème brulée shade. Samples were provided to validate his choice. In addition to choosing the right style and shade, the customer also needed to be sure of the product’s durability in a commercial environment.

Here, the customer is king. He chose the material that best matched his vision of the bench.

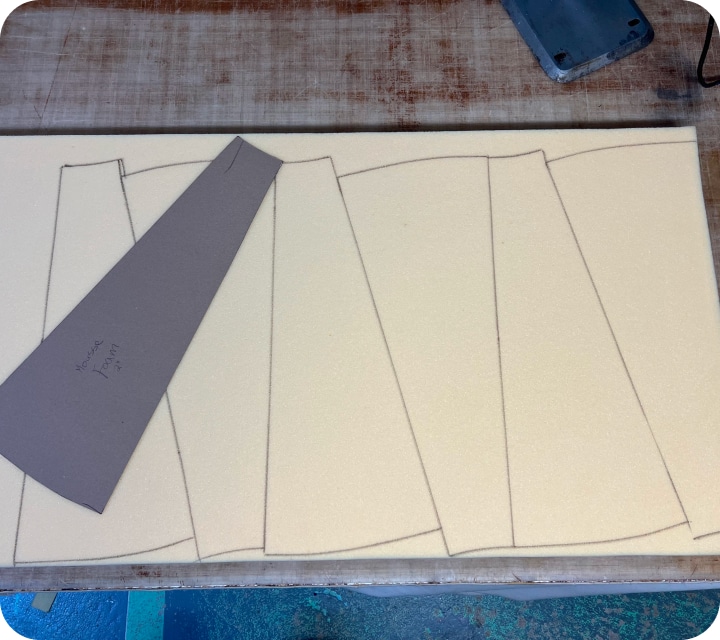

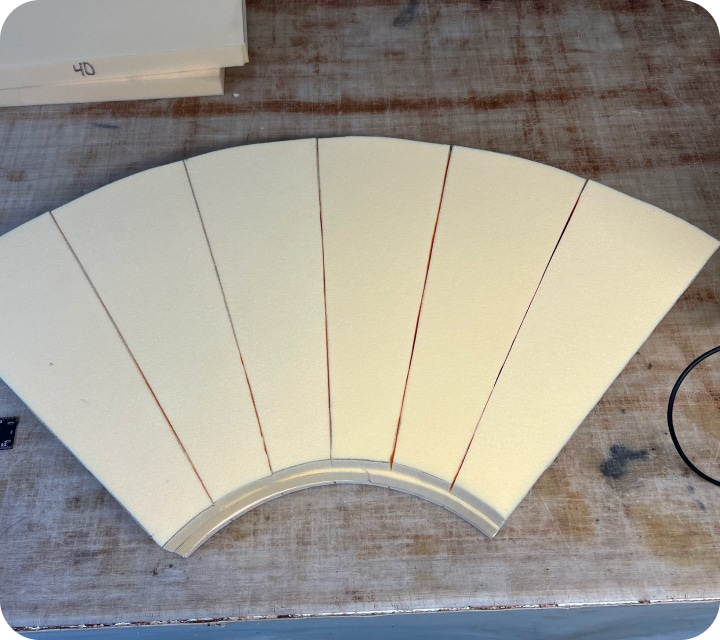

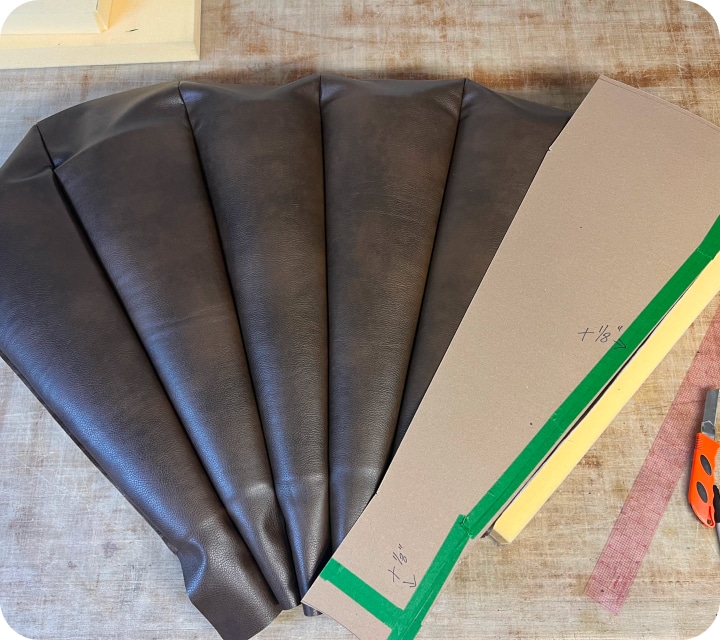

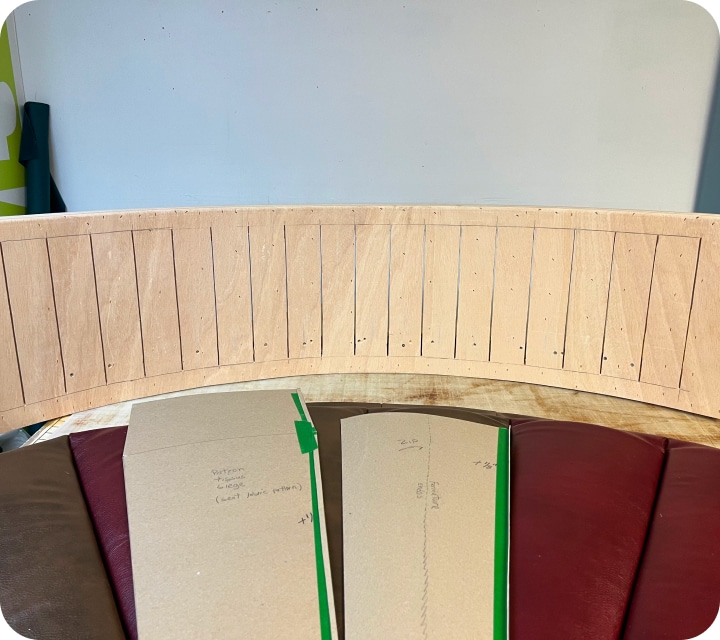

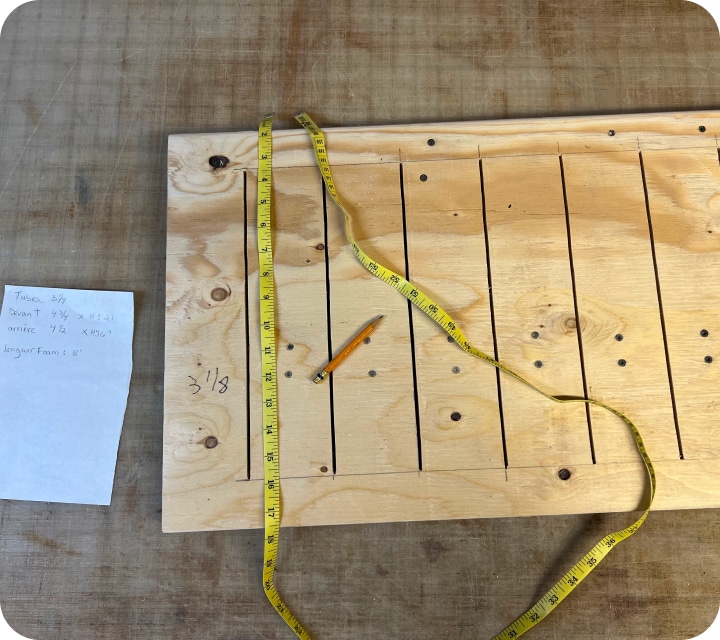

In this project, the rounded sections posed an additional challenge for the upholstery, particularly for a fabric made from flutes assembled to cover all the seats and backrests. Shown here are the steps involved in arriving at the final pattern for one of the 4 rounded seat sections of the final bench seat. The same process had to be repeated for each corner with a different radius.

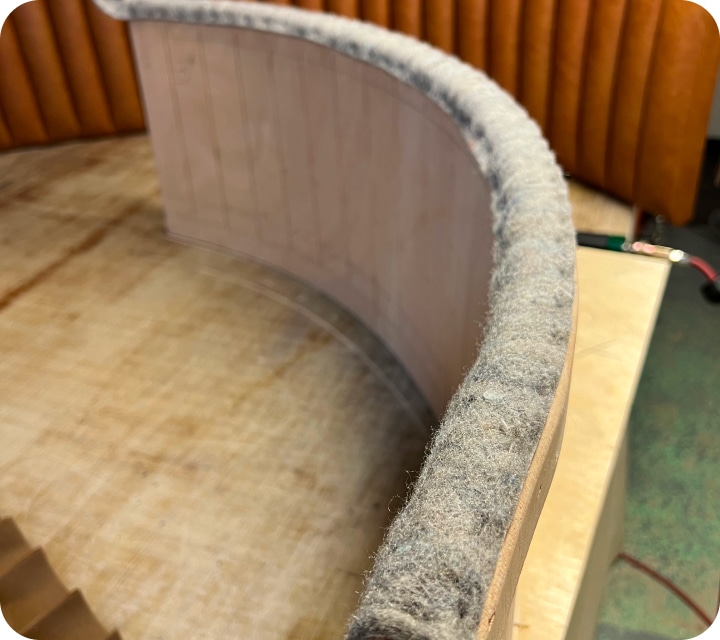

Once the patterns were created, the materials could be cut, assembled and then installed to cover each panel sections. Here, slots in the backs allow the padded and covered elements to be positioned and kept in place with tabs.

Once assembled and upholstered, panels were installed in the resto-bar. This was the last step to create the benches.